In the world of modern manufacturing, innovation is the key to staying ahead. Aluminium extrusion has emerged as a game-changing process that significantly enhances product design and functionality. This versatile technique allows for the creation of complex shapes, precise tolerances, and efficient production. In this article, we’ll delve into the various ways in which aluminium extrusion revolutionises product design and functionality, exploring its unique advantages, applications, and its impact on different industries.

How Aluminium Extrusion Enhances Product Design and Functionality

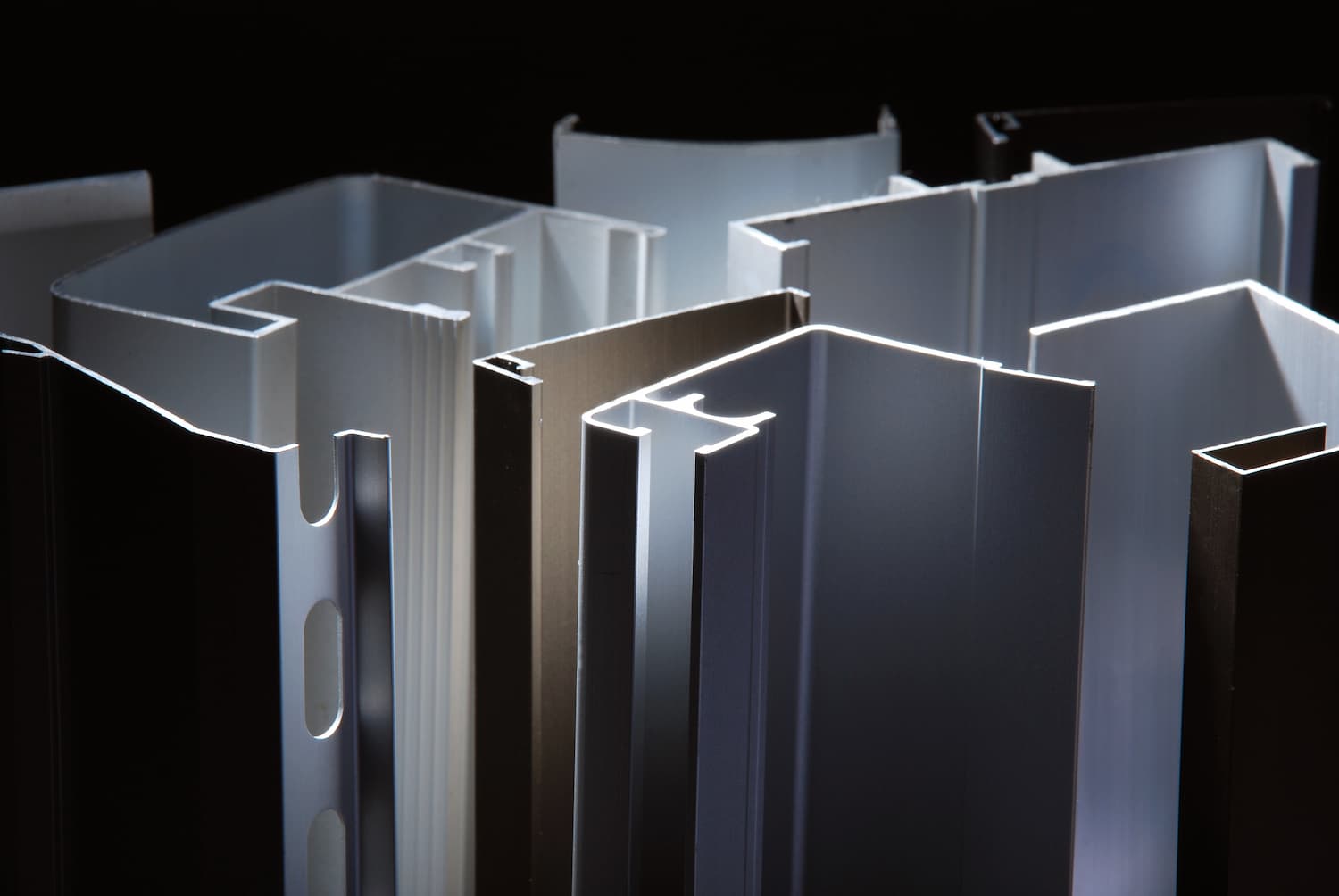

Aluminium extrusion is a manufacturing process that involves forcing heated aluminium through a shaped opening, resulting in the creation of custom cross-sectional profiles. This process offers several remarkable benefits that directly contribute to improved product design and functionality:

1. Versatility in Design

Aluminium extrusion enables designers to unleash their creativity by producing intricate shapes that might be impossible with traditional manufacturing methods. From sleek curves to intricate cutouts, the process allows for a wide array of designs that cater to both aesthetics and functionality.

2. Lightweight and Strong

One of the standout characteristics of aluminium is its exceptional strength-to-weight ratio. This property is fully harnessed through extrusion, producing components that are lightweight yet robust. This is particularly advantageous in industries such as aerospace and automotive, where reducing weight without compromising strength is crucial.

3. Precision Tolerances

Aluminium extrusion facilitates the creation of parts with precise tolerances, ensuring consistent quality and fit. This accuracy is vital in applications where components need to seamlessly integrate, enhancing the overall performance of the end product.

4. Heat Dissipation

Aluminium is an excellent conductor of heat, making it ideal for applications where efficient heat dissipation is required. Extruded aluminium profiles can be designed with built-in cooling features, ensuring that products remain thermally efficient and durable.

5. Cost-Effectiveness

The ability to produce complex shapes with minimal material waste makes aluminium extrusion a cost-effective manufacturing process. This efficiency translates to reduced production costs and ultimately more affordable products for consumers.

6. Streamlined Assembly

Incorporating extruded aluminium components often leads to simplified assembly processes. The precision-fit parts reduce the need for excessive manual adjustments, saving time and resources during production.

7. Corrosion Resistance

Aluminium possesses inherent corrosion-resistant properties due to its ability to form a protective oxide layer. This characteristic makes extruded aluminium products particularly suitable for outdoor or marine applications.

8. Sustainable Solution

Aluminium is highly recyclable, and extrusion further contributes to sustainability by minimising material waste during production. This eco-friendly aspect aligns with the growing demand for environmentally conscious products.

9. Customisation Possibilities

Aluminium extrusion accommodates a wide range of finishes, including anodizing, painting, and powder coating. This versatility allows manufacturers to create products that not only perform exceptionally but also align with branding and aesthetic preferences.

10. Seamless Integration

Extruded aluminium components often integrate multiple functions into a single part, reducing the need for additional components. This integration enhances product functionality while simplifying the overall design.

Applications Across Industries

The impact of aluminium extrusion on product design and functionality spans across various industries, each benefiting from its unique attributes:

Automotive

In the automotive sector, aluminium extrusion is instrumental in producing lightweight yet structurally sound components. From chassis elements to engine parts, the versatility of extruded aluminium leads to fuel-efficient vehicles without compromising safety.

Architecture and Construction

Architects and construction professionals embrace aluminium extrusion for its ability to create intricate facades, durable window frames, and energy-efficient structures. The lightweight nature of aluminium reduces the load on buildings while maintaining structural integrity.

Electronics

The electronics industry capitalises on aluminium extrusion’s heat dissipation capabilities to create efficient heat sinks for devices prone to overheating. This ensures that electronic components perform optimally and have extended lifespans.

Consumer Goods

From sleek smartphone casings to ergonomic furniture frames, aluminium extrusion enhances the aesthetics and functionality of various consumer products. The lightweight nature and customizability of aluminium profiles cater to the demands of modern consumers.

Industrial Machinery

Heavy-duty industrial machinery benefits from the strength and durability of aluminium extruded components. The lightweight yet robust nature of these parts contributes to the overall efficiency and longevity of machinery.

FAQs

Q: Is aluminium extrusion suitable for small-scale production?

A: Absolutely! Aluminium extrusion is adaptable to various production scales, making it a viable option for both small-scale and large-scale manufacturing.

Q: Are there limitations to the shapes that can be achieved through aluminium extrusion?

A: While aluminium extrusion offers a wide range of design possibilities, extremely intricate shapes might require additional machining processes. However, in most cases, designers can achieve their desired shapes through extrusion alone.

Q: Can extruded aluminium components be used in corrosive environments?

A: Yes, extruded aluminium is naturally resistant to corrosion due to its oxide layer. For particularly harsh environments, additional surface treatments can further enhance its corrosion resistance.

Q: Does aluminium extrusion contribute to sustainable manufacturing?

A: Yes, aluminium extrusion is considered environmentally friendly due to its efficient use of materials and recyclability. It aligns with the principles of sustainable manufacturing.

Q: What industries benefit the most from aluminium extrusion?

A: Industries such as automotive, aerospace, architecture, electronics, and consumer goods find significant value in aluminium extrusion due to its lightweight, strong, and customizable properties.

Q: Can aluminium extrusion improve the thermal performance of products?

A: Certainly. Aluminium’s exceptional thermal conductivity makes it an excellent choice for applications that require heat dissipation, such as electronics and industrial machinery.

Conclusion

Aluminium extrusion is a transformative manufacturing process that has redefined how products are designed and function. Its unique blend of versatility, strength, precision, and sustainability makes it a preferred choice across various industries. From enhancing the aesthetics of consumer goods to revolutionising the performance of industrial machinery, aluminium extrusion continues to shape the future of innovative design and functionality.